Throttle Rod binding

Moderator: Site Administrators

-

71Satellite98661

- GTX (RS)

- Posts: 245

- Joined: Sun Apr 21, 2013 7:14 pm

- My Cars: 71 Satellite

70 Challenger

07 300C SRT8

13 Ram C/V (Caravan) work-issued - Location: Vancouver, WA

Throttle Rod binding

In a quest to find out why this 440 was low on power at full throttle I found that the fast idle choke adjustment on my Holley 3310 was hitting the passenger side of the intake juts below the carburetor mating surface. This is an Edelbrock RPM with no carb spacer. I removed that piece from the throttle shaft as a temporary fix for the sake of moving forward. Now I have an issue with the one piece throttle rod reaching the end of the stroke before the carb is at wide open throttle. If I adjust the throttle rod to achieve WOT, the throttle rod is then "too short" and will no doubt shorten the life of the 727. Because this is an aftermarket Holley with the mandatory throttle lever adaptor is that my issue or do I possible have a throttle rod for a 2-bbl engine? It seems a three piece setup would allow for the adjustment I need but locating that setup may be expensive. I am not considering a Lokar cable at this time but may have to. I've attached a photo of miscellaneous parts of throttle rods and shift linkage thay may help get me there but don't think I have a complete 3-piece set up. Any thoughts?

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Throttle Rod binding

I don't know the auto trans kickdown linkage all that well. But is the trans original to the car? My thinking is that the arm on the transmission might be wrong, ( too short) and that is binding up the travel length. A picture of the trans connection at the carb might be helpful too. Since there were separate pieces for B and RB height blocks . And just in case you don't have the manual for reference...

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

-

71Satellite98661

- GTX (RS)

- Posts: 245

- Joined: Sun Apr 21, 2013 7:14 pm

- My Cars: 71 Satellite

70 Challenger

07 300C SRT8

13 Ram C/V (Caravan) work-issued - Location: Vancouver, WA

Re: Throttle Rod binding

Thank you for the reply. Now that you mention it, I think this trans is out of a 66-67 Imperial. Not sure where the throttle rod came from though. You might be right with the lever at the transmissino being too short. Today I noticed that the throttle rod at the carb end is actually "bottoming out" on the bracket itself (attaching to the intake manifold). I am realizing what a hodge-podge this set up is of mine

Here are some photos. The geometry at the carb looks pretty wonky now that I see it in photos...

Here are some photos. The geometry at the carb looks pretty wonky now that I see it in photos...

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Throttle Rod binding

Ok.. first... "WONKY"? What side of the pond are you from?

Now seriously.

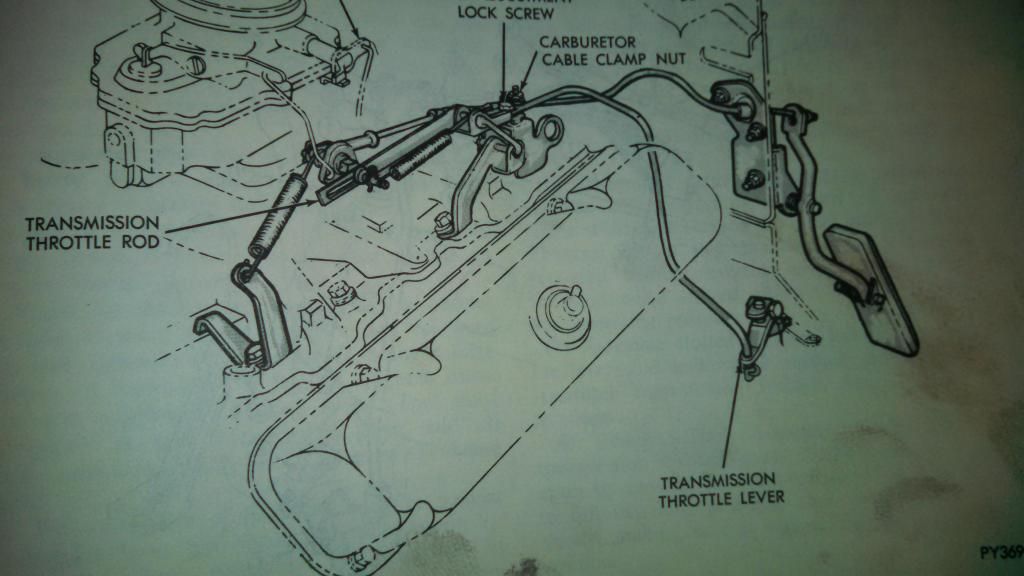

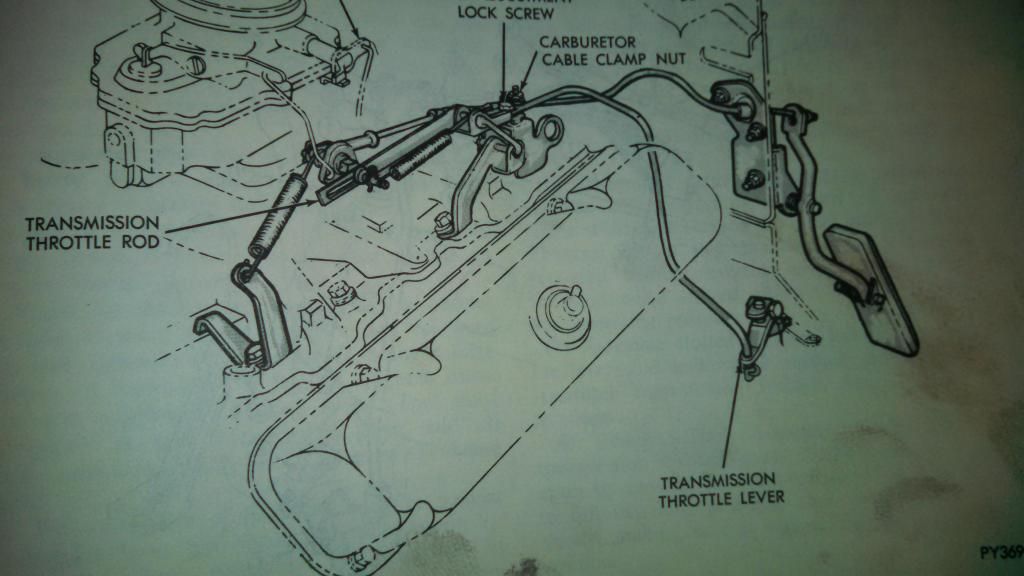

1. That is a Performer RPM manifold .. correct? It appears to be because of the runner and the height of the carb, resulting in the steep angle down to the linkage. The "adjustment" to the throttle cable clamp is close to what I had to do as well .

2. Look at your set up vs. the factory picture of the single rod. Look at the pivot link in each picture, ( where the front of the rod attaches to the manifold bracket). The factory has the link forward at rest ( idle position), yours is angled back at rest. For some reason, your rod is positioned back further at the idle position. That is where you're losing the travel.

3. Now look at the single rod in the factory picture. It has the adjustment on the top, by the engine, and yours is down by the transmission. I think this is where the problem is. You need to change to that style rod and adjuster shown in the factory picture. That should give you the play and full range you're going to need to get the full travel and make the proper adjustment- even with the sharp angle with the high-rise manifold.

4. Out of the linkage parts you have pictured, looking at the one piece rods from left to right, I would think the 1st rod maybe, 2nd possibly and 3rd more than likely( and the one I would start with), would be the proper part. 4 and 5- I seriously doubt it.

That's where I would start. Use the factory print as a guide as to what parts to use and how they should be aligned. The wonky ( I love that word ) angle may not be much of a factor if there is enough adjustment. I will post the procedure for making the proper adjustment of the linkage tomorrow. It's 1:30 AM and I need to get to bed. This getting old crap isn't working. I was supposed to die young and handsome

) angle may not be much of a factor if there is enough adjustment. I will post the procedure for making the proper adjustment of the linkage tomorrow. It's 1:30 AM and I need to get to bed. This getting old crap isn't working. I was supposed to die young and handsome

Now seriously.

1. That is a Performer RPM manifold .. correct? It appears to be because of the runner and the height of the carb, resulting in the steep angle down to the linkage. The "adjustment" to the throttle cable clamp is close to what I had to do as well .

2. Look at your set up vs. the factory picture of the single rod. Look at the pivot link in each picture, ( where the front of the rod attaches to the manifold bracket). The factory has the link forward at rest ( idle position), yours is angled back at rest. For some reason, your rod is positioned back further at the idle position. That is where you're losing the travel.

3. Now look at the single rod in the factory picture. It has the adjustment on the top, by the engine, and yours is down by the transmission. I think this is where the problem is. You need to change to that style rod and adjuster shown in the factory picture. That should give you the play and full range you're going to need to get the full travel and make the proper adjustment- even with the sharp angle with the high-rise manifold.

4. Out of the linkage parts you have pictured, looking at the one piece rods from left to right, I would think the 1st rod maybe, 2nd possibly and 3rd more than likely( and the one I would start with), would be the proper part. 4 and 5- I seriously doubt it.

That's where I would start. Use the factory print as a guide as to what parts to use and how they should be aligned. The wonky ( I love that word

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Throttle Rod binding

From the 71 Book on how to adjust the single section throttle rod... I may paraphrase here in couple places to save time, but most will be verbatim from the book. The purpose of this adjustment is to take out all the slop/ slack/ play between the carb lever pin and the transmission lever WITHOUT PRE-LOADING IT IN EITHER DIRECTION! Very important. The rod may want to rotate from side to side a little bit, ( which is normal from the way it is connected to the transmission lever), what we are concerned about is the back and forth play between the two. The reason for this is that the throttle rod controls a pressure circuit in the transmission which governs the speed at which the shifts are made.

1) Follow the detailed instructions on lubricating the linkage. (IE, just make sure it's loose and free moving- I don't think that is an issue since your parts look to be new and not all crudded up.)

2) Disconnect choke at carb or block the choke in the wide open position. Open throttle slightly to release the fast idle cam, then return carb to curb idle position.

3) Loosen the transmission throttle rod adjustment lock screw.

4) Use special tool c-4160 to hold the transmission lever forward against its stop... (Ok since no one has this tool, either have a friend hold the LEVER ( not the rod) forward against its internal stop. OR rig up a way to hold the transmission lever forward against its internal stop. A strong spring or wire (better) would work- just so there is no influence applied to the Throttle rod and the lever is held tight forward with no play to the rear.)

5) Adjust the transmission rod at the carb by pushing forward on the retainer and rearward on the rod ( opposite directions) with a slight force to remove all backlash. See fig 19, ( below). Tighten transmission rod adjustment locking screw. Tool, ( spring /wire/ friend ), must be in place at the transmission lever and all backlash removed when tightening the lock screw.

NOTE: The rear edge of the link slot must be against the carb lever pin during this adjustment.

6) remove the tool ( spring /wire/ friend) from the transmission throttle lever. check the linkage freedom of operation by moving the slotted link at the carb to the full rearward position and then allow it to return slowly, making sure it returns to the full forward position.

7) Re connect the choke linkage or remove the blocking fixture.

Now if you get this done and the carb still will not reach wide open, then we'll need to look at the lever on the transmission. Or if the lever doesn't move the full swing- or 80-90% of it. I have to check, or someone could chime in that knows for sure, how far the lever is supposed to move in its arc of travel. I do not know that information absolutely positively for sure.

1) Follow the detailed instructions on lubricating the linkage. (IE, just make sure it's loose and free moving- I don't think that is an issue since your parts look to be new and not all crudded up.)

2) Disconnect choke at carb or block the choke in the wide open position. Open throttle slightly to release the fast idle cam, then return carb to curb idle position.

3) Loosen the transmission throttle rod adjustment lock screw.

4) Use special tool c-4160 to hold the transmission lever forward against its stop... (Ok since no one has this tool, either have a friend hold the LEVER ( not the rod) forward against its internal stop. OR rig up a way to hold the transmission lever forward against its internal stop. A strong spring or wire (better) would work- just so there is no influence applied to the Throttle rod and the lever is held tight forward with no play to the rear.)

5) Adjust the transmission rod at the carb by pushing forward on the retainer and rearward on the rod ( opposite directions) with a slight force to remove all backlash. See fig 19, ( below). Tighten transmission rod adjustment locking screw. Tool, ( spring /wire/ friend ), must be in place at the transmission lever and all backlash removed when tightening the lock screw.

NOTE: The rear edge of the link slot must be against the carb lever pin during this adjustment.

6) remove the tool ( spring /wire/ friend) from the transmission throttle lever. check the linkage freedom of operation by moving the slotted link at the carb to the full rearward position and then allow it to return slowly, making sure it returns to the full forward position.

7) Re connect the choke linkage or remove the blocking fixture.

Now if you get this done and the carb still will not reach wide open, then we'll need to look at the lever on the transmission. Or if the lever doesn't move the full swing- or 80-90% of it. I have to check, or someone could chime in that knows for sure, how far the lever is supposed to move in its arc of travel. I do not know that information absolutely positively for sure.

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

-

71Satellite98661

- GTX (RS)

- Posts: 245

- Joined: Sun Apr 21, 2013 7:14 pm

- My Cars: 71 Satellite

70 Challenger

07 300C SRT8

13 Ram C/V (Caravan) work-issued - Location: Vancouver, WA

Re: Throttle Rod binding

Excellent details and advice Road Chicken, many thanks! Tonight after work I'll swap out throttle rods and get the adjustment up at the carburator end where it belongs. Getting that link bar up or leaning forward at idle seems to be one of initial goals to getting this set up properly. After our discussion, I think that is definitely the root of this problem. I need to verify, but the lever at the transmission probably has plenty of travel left. If not, I will entertain the idea of a longer lever. Again, thank you very much for your advice. Paraphrasing the FSM helps big time!

-

71Satellite98661

- GTX (RS)

- Posts: 245

- Joined: Sun Apr 21, 2013 7:14 pm

- My Cars: 71 Satellite

70 Challenger

07 300C SRT8

13 Ram C/V (Caravan) work-issued - Location: Vancouver, WA

Re: Throttle Rod binding

We might be in business now. I took one of the spare throttle rods, bisected a straight section, threaded both cut ends with 3/8-16 tap, added coupling and jam nuts then elongated the slot at the upper end of the throttle rod by about 3/4". I now have full stroke of both the throttle rod and carburetor throttle. Adjustments per FSM now leaves the adjustment slot right in the middle for fine tuning and I think I'm ready for a test run. Thanks for the help, I've added a couple of photos of the modification...

- road chicken

- GTX (RS)

- Posts: 660

- Joined: Thu Oct 09, 2003 11:21 pm

- Location: SE WI

Re: Throttle Rod binding

Thats what you have to do to make the 383 rod work on a 440 to make up for the extra height difference. Good luck.71Satellite98661 wrote:We might be in business now. I took one of the spare throttle rods, bisected a straight section, threaded both cut ends with 3/8-16 tap, added coupling and jam nuts then elongated the slot at the upper end of the throttle rod by about 3/4". I now have full stroke of both the throttle rod and carburetor throttle. Adjustments per FSM now leaves the adjustment slot right in the middle for fine tuning and I think I'm ready for a test run. Thanks for the help, I've added a couple of photos of the modification...

4th generation B bodys- there is no substitute.

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs

68 383, Street Demon 750, RPM top end,484/284/108 poo poo cam "-5 spd 4:10 SG, 4whl disk, Helwig Anti-Sway, Poly bushings,Firm Feel Box, HD Linkage, 1" t-bars, 7 leafs Springs